Digital Wicker

Circular Construction

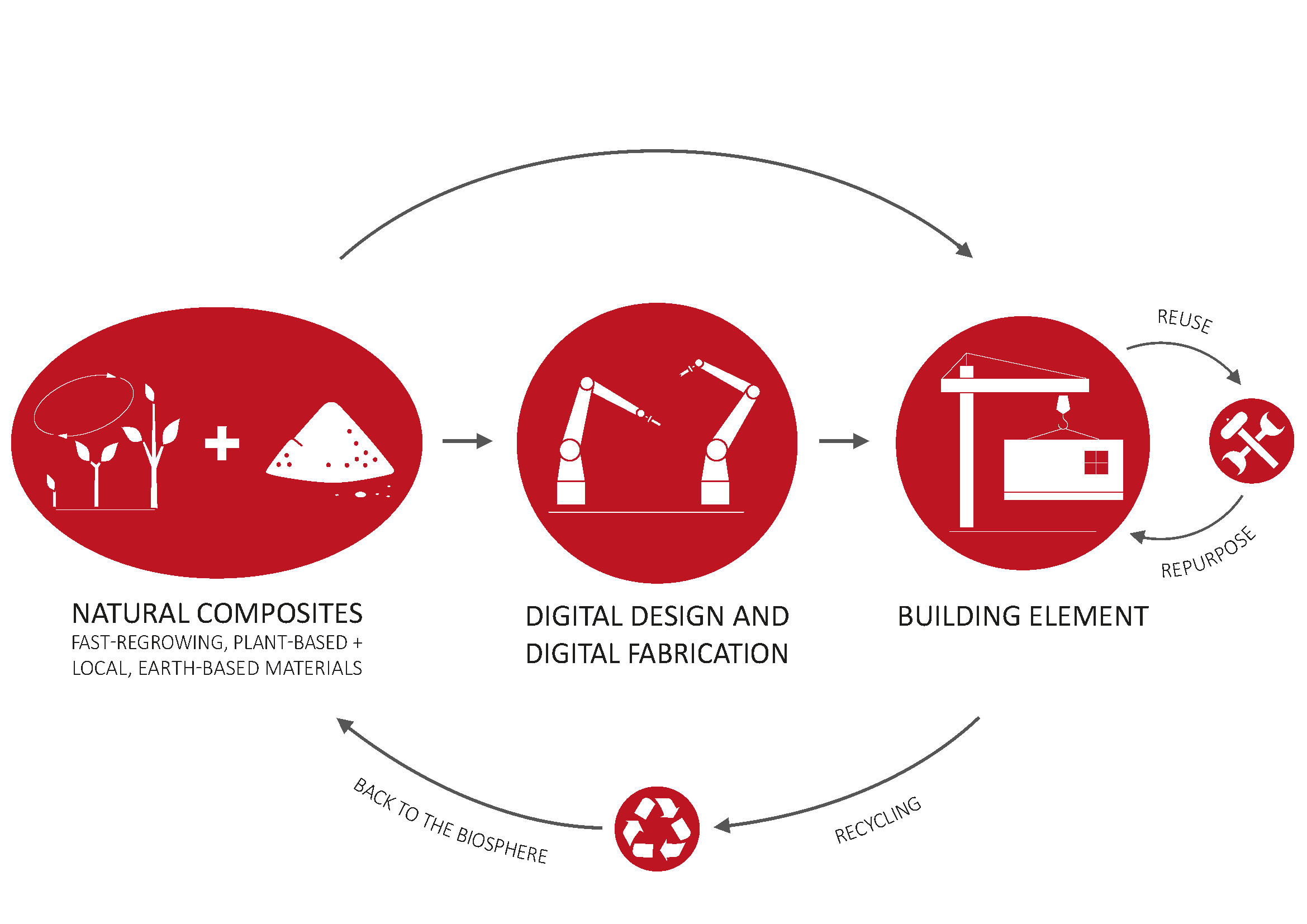

As the building sector is responsible for more than a third of the global resource consumption (Klep, 2015), a shift towards circular construction cycles represents a major opportunity for the construction industry to curtail the depletion of raw materials. Digital Wicker - DDF’s first Master Studio - aims to develop circular construction concepts that are enabled by digital design and fabrication and to explore correlated novel design and construction repertoires. More specifically, it focuses on implementing circular biological cycles, in which renewable plant-based resources are returned to the biosphere at the end of their life cycle. While wood is the only significant renewable building material today, truly sustainable development may be achieved with the diversification of renewable materials, to avoid dependence on a single resource. Therefore, fast-regrowing plant-based materials - such as willow and poplar - in combination with alternatives to conventional aggregates - namely clay and loam - are the focus of the investigations in Digital Wicker. Digital design and fabrication methods can address these global challenges and enable novel concepts of digital circular construction through tailored processes for renewable and natural materials. Digital Wicker is the first step towards the creation of a full-scale research demonstrator, which will be produced in the Summer Semester 2022.

Wicker turns digital

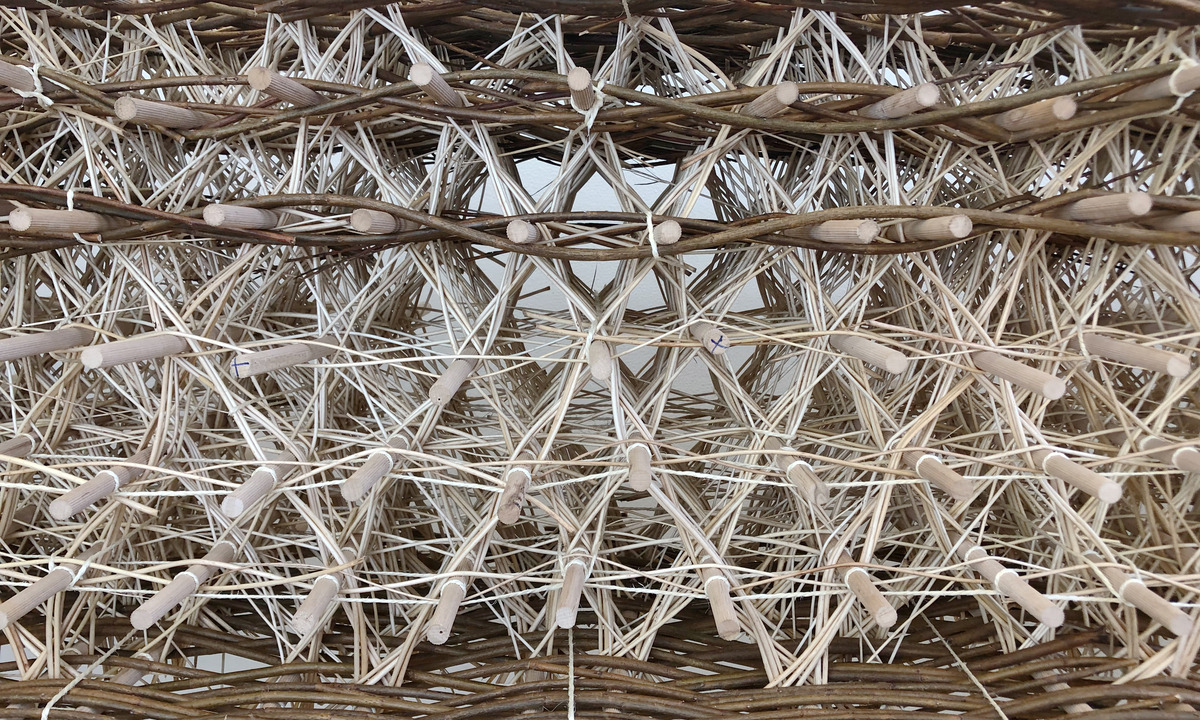

Wicker weaving, a technique where long thin sticks, stems or reeds are woven together to make baskets, represents an important analogy of how to exploit geometry and textile techniques to give structural stiffness not otherwise inherent in the materials. Typical of traditional manufacturing, “wicker” expresses the intention of looking back at local, renewable materials and techniques that used to be part of the architectural and construction repertoire but have been sidelined in the first industrial revolution. One of such construction methods is exemplified by the European vernacular wattle and daub, in which renewable and natural materials are combined into a low-impact sustainable composite. In light of the fourth industrial revolution, which is envisioned as a fusion of technologies blurring the lines between the physical, digital and biological spheres (Schwab, 2017), digital design and fabrication can sustain the industrialisation of natural materials. They can accommodate for deviations and abnormalities, which currently represent one of the biggest obstacles in standardised serial production systems. Thanks to their flexibility and versatility, digital production techniques enable architecture components that are designed and fabricated with a high resolution and articulation of structure and materiality but also of graded transparency and rich visual details. Finally, they can enable the large-scale, automated production of components thus facilitating their implementation in construction, both in terms of construction technology and economics.